For garment manufacturers, crafting the perfect shirt often hinges on the details, and achieving crisp, consistent cuffs can be a constant challenge. Traditional ironing methods can be time-consuming, labor-intensive, and prone to inconsistencies, especially when dealing with diverse fabrics and varying production volumes.

Here’s a glimpse into the common challenges faced by manufacturers when it comes to shirt cuffs:

Inconsistent shaping: Hand ironing can lead to uneven pressure and shaping, resulting in distorted or poorly defined cuffs.

Time-consuming process: Traditional methods require skilled operators and significant time, impacting production efficiency and scalability.

Fabric limitations: Delicate fabrics or complex cuff designs might pose challenges for manual ironing, risking damage or compromising the desired look.

Labor costs: Manual ironing necessitates skilled labor, adding to overall production costs.

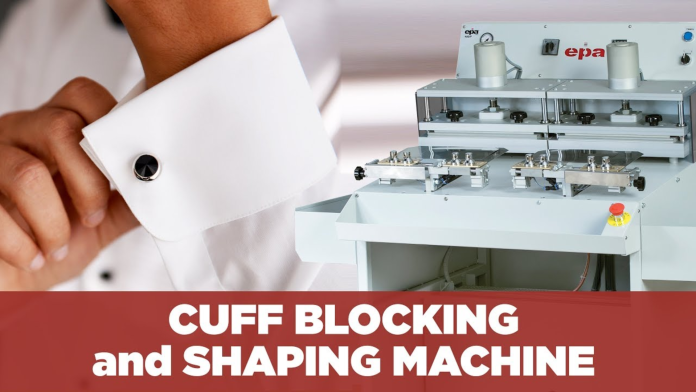

Introducing the EPA-405 Cuff Shaping and Blocking Machine: Your Solution to Perfect Cuffs

AM Automation Solutions, the proud distributor of EPA Akin machinery in India, brings you the revolutionary EPA-405 Cuff Shaping and Blocking Machine. This innovative solution addresses the aforementioned challenges head-on, empowering manufacturers to achieve flawless, consistent cuffs with remarkable efficiency.

Here’s how the EPA-405 transforms shirt cuff production:

Precision and consistency: The machine’s automatic mold drive ensures uniform pressure and shaping, guaranteeing identical, perfectly formed cuffs every single time.

Unmatched efficiency: With a capacity of 300 pieces per hour, the EPA-405 significantly boosts production speed compared to manual methods.

Versatility for all fabrics: Adjustable digital temperature control and pressing settings allow the machine to adapt to various fabric types, from delicate silks to sturdier linens, without compromising quality.

Simplified operation: The user-friendly interface with an easy toggle switch and fast mold-changing system minimizes training time and streamlines the production process.

Reduced labor costs: By automating the cuff shaping and blocking process, the EPA-405 minimizes reliance on manual labor, leading to significant cost savings.

At AM Automation Solutions, we understand the unique needs of garment manufacturers. We’re not just distributors; we’re your trusted partners in achieving operational excellence.

Here’s what sets us apart:

Expert advice: We offer in-depth consultations to help you choose the ideal EPA-405 configuration for your specific requirements.

Comprehensive support: Our team provides seamless installation, training, and ongoing maintenance to ensure your machine operates at peak performance.

Commitment to your success: We’re dedicated to helping you maximize efficiency, productivity, and profitability in your shirt manufacturing operations.

Contact AM Automation Solutions to learn more about this machine and schedule a demonstration.

Website link: https://amautomation.com/product/epa-405-cuff-shaping-and-blocking-machine/

Email us at: info@amautomation.com

Please reach out to us at +91 9884071180.

Together, let’s revolutionize the way you craft the perfect shirt, one flawlessly shaped cuff at a time!